SAM Impression Materials

Why you should use the only specific impression material specifically formulated for sequential aligner therapy

The process of taking impressions is simply to transfer 3-D physical data from the patient's mouth as accurately and comfortably as possible. The greater the transfer accuracy, the better the aligners will fit, the greater the predictability of the treatment plan and increased chance of movements being expressed completely.

As a major complicating factor, the mouth is a very wet environment. The impression material must be able to replicate hard and soft tissue structures with minimal hygroscopic distortion. In addition, impressions for sequential aligners are transported under varying unpredictable conditions of temperature and air pressure across the world to Align Technologies manufacturing facility in Juarez, Mexico. Hence, the impression material must be immune to many variables.

Impression materials are used with a wide range of clinical techniques for accurate capture of the critical elements for successful sequential aligner therapy with Invisalign; they all require excellent predictability and great latitude of clinical application. Most practitioners do not have the time to address the science and technology that goes into the development of a successful impression material, the behind-the-scenes work that facilitates and optimizes chair side procedures. In fact, the many impression technology advances of the past 25 years are easy to forget. Rubber base (slow setting and foul smelling) was the most common and best available material into the mid 1970s. In the late 1970s, hydrophobic polyvinyl impression materials were introduced, quickly gaining popularity and today they remain the most commonly used impression materials world wide. In the mid 1990s, truly hydrophilic poly-vinyls that could take accurate impressions of wet intraoral surfaces were introduced. Other enhancements included improved material strength, tear-resistance and repeated pourability.

The ideal impression material reflects all the hard- and soft-tissue details, including their static relationship, in the mouth. This data is transferred during the relatively short working time (30 to 90 seconds) and fixed (polymerized) into the impression material memory during the setting time (60 to 240 seconds). The shape of the impression is unalterable after this. Impressions should work perfectly the first time, every time. Given the degree of discomfort, time consuming and expensive nature of capturing dual full arches for Invisalign treatments, the importance of utilising the most efficacious materials is paramount.

The cost of retaking an impression includes not only materials such as trays, impression materials but also chair time. Vinyl polysiloxane impression materials are accurate, fast, predictable, and, last but not least, easy-to-use. The range of available materials offers various properties and specifications that suit every procedure and every practitioner. The following guide identifies some of the selection criteria that can be used by the dentist in determining which impression materials are most appropriate to the task at hand. The SAM range of VPS impression materials have been specially formulated for capturing the whole arch and relevant soft tissues in the deadly accurate light body material with significant support from a VPS putty.

Shark fin test

This essentially measures flow in an impression material. The ideal material would flow until it is ready to polymerize and then snap set. Unfortunately, most addition silicones have a slow setting time rather than a snap set. So the viscosity increases soon after the material is mixed and continues to increase until the impression polymerizes. Polyether impression materials provide increased flow at the end of the setting time with a sharper set time (i.e., polymerization occurs rapidly at the end of the setting time). For example, this is especially important when making impressions of multiple abutments when you need all the working time you can get.

Contact Angle

This is a measure of how well the material wets another. Surface wetting is the ability of a liquid to spread over a surface. The wetting of a solid by a liquid can be measured by the contact angle. A contact angle of 0 degrees indicates complete wetting (hydrophilic). Higher contact angles (greater than 900) mean lower wetting (more hydrophobic). Impression materials with low contact angles have good wetting and intimate adaptation of the impression material to the tooth surface.

Surfactants lower the contact angle of the set PVS impression material and reduce voids in the recovered cast. In impression materials, two contact angle measurements are important. One is the contact angle on the unset material, which measures the ability of the impression material to wet or adapt to the oral tissues. The other is the contact angle on set material, which measures the ability of stone to wet the impression. The first measurement provides good surface detail of the prepared tooth while the second measurement shows how many bubbles will be present in the cast. However, the contact angle made against unset impression material is generally higher than against set material. The surfactant in the freshly mixed VPS impression material must migrate to the surface to make that surface hydrophilic.

Since it takes time for the surfactant to migrate, silicone impression materials are not actually hydrophilic on initial contact with the moist oral tissue. Recent studies have focused on measuring the contact angle of the unset impression material. When addition silicone and polyether impression materials are compared, the initial contact angle is lowest with polyether impression materials. In contrast to addition silicone impression materials, polyether impression materials are hydrophilic with a high affinity to moist surfaces, such as tooth and moist, soft tissue. Polyether materials have intrinsic hydrophilicity compared to the hydrophilicity produced by adding surfactants to the impression material. The hydrophilicity of polyethers is due to the polarity of the polyether molecule.

Moisture displacement

Recently, a number of articles have examined the hypothesis that a hydrophilic impression material can displace moisture in the sulcus or on metal dies. Some studies have reported improved wetting with newer polyvinylsiloxane impression materials; however, a clinically dry field produces more predictable results with any impression material. Also, haemorrhage and moisture control is essential for making excellent impressions.

Tear strength

When an impression is removed from the mouth, it is stretched in some areas and compressed in others. Particularly vulnerable to stretching are the thin fins of impression material in the sulcus, where the impression material is stretched as the impression is removed. Initially, these areas stretch and if the pressure is released, the material returns to its original size and shape. Unfortunately, if stretching continues, it is stretched to a point of “no return” (the yield point) in which permanent distortion occurs. If stretching continues, the impression tears (tear strength). Impression materials that deform and do not tear may look as though all the margins have been captured with even flash past the margins. But they may be inaccurate due to the distortion produced during impression removal. Rapid impression removal tends to maximize recovery from deformation. Thus, the set impression should be removed from the mouth with a rapid pull (as far as is practicable), and not “teased” out slowly.

Ideally, the space remaining after the retraction cord is removed is 0.3-0.4 mm. No differences in tear strength occur between elastomeric impression materials when the impression material is 0.2 mm; however, when the sulcus is retracted less than 0.2 mm, greater distortion is produced in the marginal area of the impression. Tear strength depends upon several factors: the amount of gingival retraction since thin areas of impression material are more likely to distort and tear, the depth of the subgingival margin, the amount of hemorrhage that produces flaws in the impression thus lowering tear strength, and sharp edges and rough preparations that increase the force required to release the impression material from the surface.

Viscosity

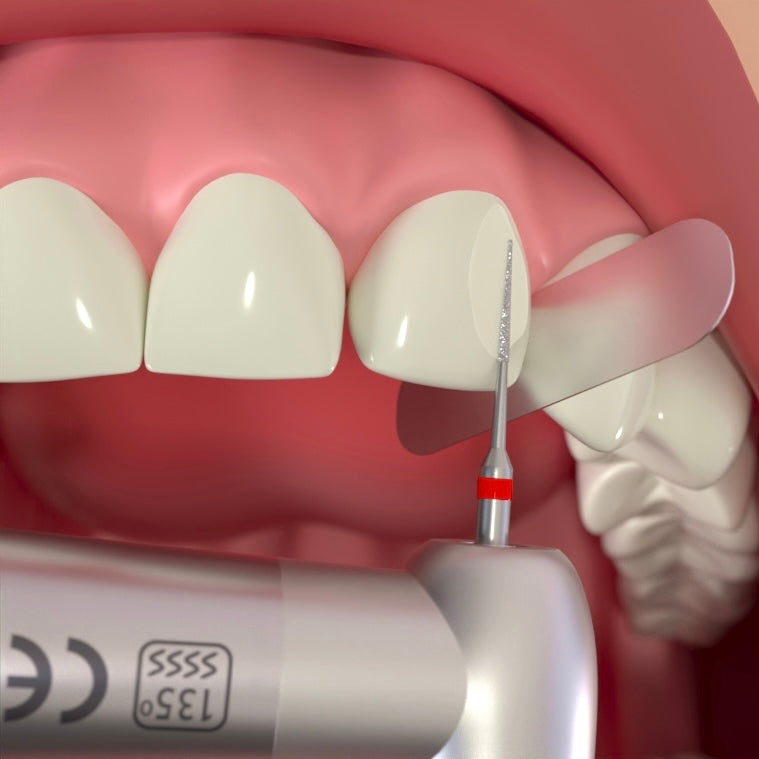

Impression materials are supplied in four viscosities ranging from low (syringe or wash material), medium or monophasic, high (tray or heavy body), and very high (putty). As the filler content of the impression material increases, the flow of the material decreases. Viscosity also is reduced by shearing forces, allowing a medium-body impression material to have lower viscosity when injected into the sulcus through a syringe tip, but still have a high enough viscosity to avoid slumping when loaded into an impression tray. Being able to capture a subgingival margin is difficult, and requires the impression material to be placed apical to the prepared tooth margin.

Being able to capture this area in the impression requires adequate retraction and placement of the low-viscosity material into the sulcus. Allowing the cord to remain in the sulcus for 10 minutes produces maximum retraction. But most clinicians do not allow this much retraction time. If little retraction is produced, then a thin fin of impression material is expressed into the sulcus. This fin is susceptible to distortion. If a high-viscosity impression material is used with less retraction, then the impression material will not flow to the base of the sulcus and incompletely capture the prepared margin. Low-viscosity materials flow into the sulcus easier than high-viscosity materials. So the ability of the impression material to duplicate the marginal area is dependent upon the viscosity of the impression material and the retraction time. If the prepared tooth margin is subgingival, you can improve your chances for clinical success by increasing retraction time and using a low-viscosity syringe material.

Working and setting time

Working time is measured from the start of mix and includes time to manipulate and syringe the material around the tooth. Working time allows the impression material to be placed in the tray and syringe and injected into the sulcus. The setting time for impression materials is the time the material needs to be in place in the oral environment to polymerize. Elastomeric impression materials have a working time of approximately two minutes and a setting time of two to six minutes (fast set vs. regular set). The setting time of all elastomeric impression materials is affected by temperature. To increase working time, refrigerate impression materials before use.

Mixing technique

An auto-mixing, dual-barrel syringe may cost somewhat more than spatulating extruded components on a pad, (and involve disposable components) but the increased ease and predictability of impression taking are well worth it. Cartridge auto-mixing provides a precise base/catalyst proportion, and a rapid, single-handed, bubble-free delivery directly onto the prepared tooth. Electrically powered mixing devices have the added advantage of eliminating the requirement for manual strength on the impression trigger.

These are larger devices, and have a greater footprint in the operatory, however. Pad spatulation is severely limited by inaccurately dispensed component amounts, a technique-sensitive manual mixing process that often incorporates air bubbles, and inefficient syringe and tray loading. Manual pad spatulation should be avoided whenever possible.

Setting time

Faster setting impression materials are very advantageous in the efficient practice. It is essential that the faster setting not compromise the impression quality by any means. Faster setting times are convenient for both patient and dentist, particularly when only one or 2 teeth have been prepared; decreased intraoral tray time is easier for the patient, and saves chair side minutes for the dentist . In most practices, faster-setting impression materials and 3 minutes start-finish are used for quadrant- or triple-tray impressions or patients with a strong gag reflex or restricted airways.

Regular set times (5 to 6 minutes) are more suited to Invisalign full arch and multiple-abutment crown and bridge impressions. The practitioner first selects the required working time for positioning the impression material onto all the prepared teeth, and then chooses the appropriate setting time.

Contaminants

Many polyvinyl materials (A silicones) are prevented from polymerizing by certain commonly used dental materials. The most common contaminant is trace sulfur (found in latex gloves) that interferes with polyvinyl polymerization, preventing complete setting. Glove lubricating powders also contain trace components of contaminating chemicals. You should avoid touching impression materials with gloves.

Eugenol materials, common in provisional cements, liners, and bases, can also inhibit polyvinyl setting. Acrylic provisional crown materials contain amines that also interfere with polymerization. Some hemostatic agents used with cord retraction may be chemically incompatible with impression catalysts, and should be washed away thoroughly, even though some polymerizationinhibiting will undoubtedly remain.

Hydrophilic versus hydrophobic

The mouth is always wet. VPS impression materials are inherently hydrophobic but can be chemically altered to make them hydrophobic. SAM impression materials are designed specifically to work in a wet environment. These are far easier and better to use.

Viscosities

Impression techniques may call for different viscosities. The clinical choice of impression material may depend on the range of viscosities in an impression line. It is essential that these varying viscosities all have the same rheology, or chemical characteristics, that are typically manufactured into product lines. It is generally not a good idea to mix components from different manufacturers into the same impression.

Flavouring

Current impression materials are either taste- or odor-neutral, or pleasantly flavored. While the patient may enjoy the experience, the flavoring chemicals often increase salivary flow during the impression taking, complicating the process unnecessarily.

Pour time

Some impression materials require a dwell or maturation time prior to the stone pour, while others can be poured immediately. You should check the instruction manual. Chairside inlay techniques, for example, require immediate pourability. Since the impression may be sent to a distant dental laboratory, a longer pouring time is important. The impression may not reach the lab until one or 2 days after mouth removal. Typically, most newer impression materials allow for a minimum of one week.

Shelf life

Similarly to other dental materials, impression materials do not last forever. You should check the expiration date on the cartridge. Use materials prior to their expiration for best results. Some materials have shorter shelf lives. Office stock should be determined by the expected utilization rate. While impression materials in bulk cost less, they become more expensive if half the stock must be thrown out due to expiration.